What if AI didn’t just analyze data, but could think, decide, and execute like an expert engineering team?

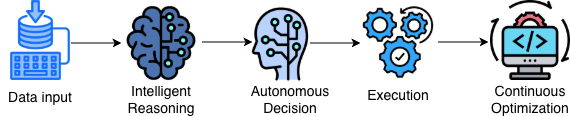

The future of industrial innovation has arrived. Agentic AI doesn’t just provide insights; it reasons, decides, and acts autonomously.

“According to the Gartner Emerging Tech Report, by 2026, over 40% of enterprise AI systems will move from assistive to autonomous decision-making—what Gartner calls the rise of Agentic AI.”

For decades, digital transformation has focused on optimizing existing processes. Traditional AI improved analytics, automated reports, and sped up calculations—but remained passive, waiting for human instructions. Today, industries are entering a new era where AI not only analyzes data but executes engineering intent independently, transforming operations from reactive to proactive. Aerospace companies, for example, are beginning to leverage this approach to accelerate design cycles and optimize complex engineering workflows.

This is the foundation of the Agentic AI model—moving from “AI as a tool” to AI as an operational capability.

The Limitations of Traditional AI in Scaling Industrial Value

Despite the implementation of AI applications in manufacturing, most legacy AI frameworks remain passive failing to be active enablers of innovation. In industries like aerospace, Engineers are overly involved in interpreting analytics rather than improving actual processes.

A traditional AI framework typically:

Optimize a step, not the full lifecycle

Provide predictions, but do not translate them into autonomous actions

Support decision-making but cannot autonomously implement changes

The result: Low AI value creation despite investing a huge amount in digital transformation. “According to McKinsey’s Industrial AI Update 2025, nearly 70% of manufacturing AI deployments fail to deliver tangible ROI, as they stop at prediction instead of driving actionable results.”

The 2025 Aerospace Shift: AI as a Collaborative Agent

In 2025, the aerospace industry is transitioning from AI that merely assists humans to Agentic AI—a collaborative engineering agent capable of reasoning, deciding, and executing autonomously.

According to Deloitte’s 2025 Aerospace & Defense Industry Outlook, organizations adopting agentic workflows in aerospace report 30–50% faster engineering cycles, reduced rework, and more predictable project timelines.

By integrating context awareness, real-time decision-making, and workflow optimization, Agentic AI enables aerospace companies to accelerate development, optimize complex simulations, and reduce operational costs.

Why Agentic AI is a Game-Changer for Industrial Leadership

PLM, as we know it, is dead — and "assistive AI" is dying with it.

The future isn’t software that helps engineers, but systems that act as engineering collaborators.

Agentic AI represents a fundamental leap in AI applications in manufacturing, unlike traditional AI, which primarily provides insights or recommendations.

The systems can:

✅ Plan

✅ Decide

✅ Execute

✅ Self-improve

Step Into the AI Agentic Era with Neodustria 🧠

Book a private walkthrough of Neodustria’s Agentic Architecture for your product lifecycle.

Request a demo

Why Neodustria Leads the Agentic AI Revolution

Neodustria goes beyond conventional AI tools by integrating physics-aware reasoning, real-time decision execution, and autonomous workflow orchestration into a unified platform. Its AI Designer’s Assistant actively participates in aerospace design, simulation, and manufacturing, ensuring faster iterations, lower prototyping costs, and higher first-pass success rates.

Guided by the philosophy of Researching the Future. Engineering the Impossible, this platform empowers engineers and product managers to accelerate product development, optimize resources, and achieve measurable ROI, setting a new benchmark for industrial leadership in the new phase of Industry 5.0.

Voice of the Engineer

"Neodustria’s AI Designer Assistant assisted our team in cutting design cycles by weeks while maintaining the precision we didn’t think was possible." – Senior Aerospace Engineer

Next in the Digital Thread Series: See how Neodustria’s Neural Factory uses physics-aware AI to cut energy use and waste while building a smarter industrial future. [Read more →]