For construction plant directors, engineering managers, and fabrication operations leaders, post-installation defects, early fatigue, and repeat rework often originate from one systemic failure: operational reality never feeds back into engineering.

Poor Engineering & Operational Data orchestration are accounts for 52% of rework of all reworks in construction, leading to billions of dollars in wasted time and cost on job sites.

When field behavior is disconnected from design, construction programs inherit the same risks project after project.

The Operational Risk Construction Teams Face

In construction manufacturing, engineering accountability often stops at handover.

Once assets are installed and commissioned:

Real site loads differ from original assumptions

Environmental exposure accelerates wear

Maintenance teams make adjustments outside engineering control

Known defects quietly reappear in future builds

This disconnect creates repeat defects, scrap, schedule disruption, and long-term asset risk. The industrial risk is not execution, but production volatility between projects.

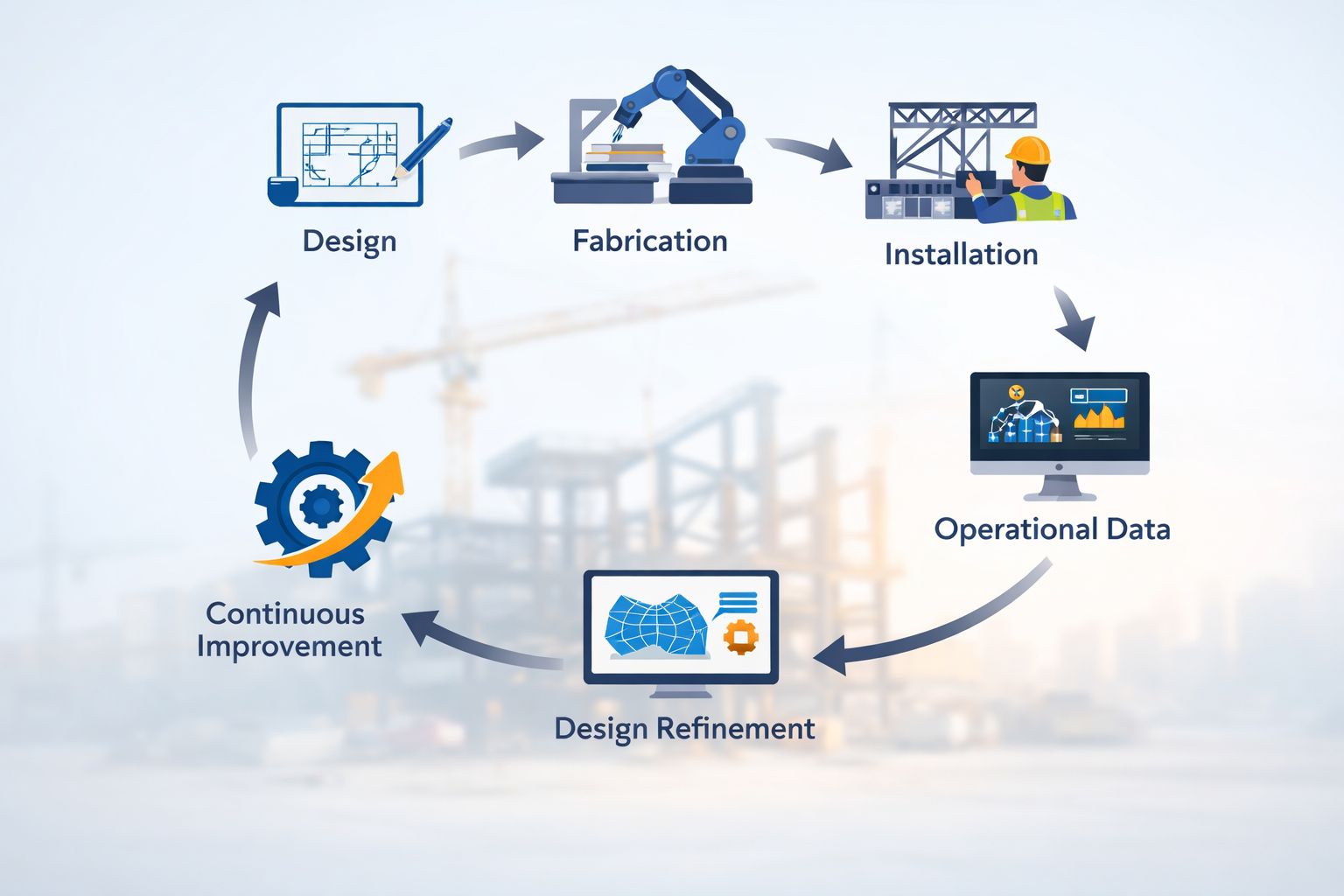

The Solution: Digital Twin Feedback Loops

Neodustria addresses this challenge by keeping the Physics-Aware Model active beyond production. Operational data, maintenance records, and as-built behavior are continuously fed back into the original engineering model, allowing design assumptions to evolve based on real-world evidence.

This approach allows construction cells to:

Monitor how assemblies perform under real loads

Identify early fatigue and degradation patterns

Adjust tolerances and interfaces based on actual evidence

Prevent recurring defects in subsequent projects

The result is adaptive engineering, where each project strengthens the next.

How the Digital Twin Feedback Loop Operates

Neodustria establishes a controlled, traceable connection between engineering and operational assets. Data captured from installed systems flows directly back to the engineering model, creating a continuous loop.

Each completed project strengthens the accuracy of future designs, ensuring that lessons learned are systematically applied. Over time, this cumulative learning significantly reduces rework, scrap, and post-installation failures, while increasing first-pass success rates.

Closed-Loop Analytics in Construction Operations

Neodustria ensures that post-production behavior is never disconnected from engineering decisions. As-maintained data stays linked to original assemblies, making field issues traceable to the design choices that caused them.

Updated models guide future fabrication and planning, giving teams a predictable path from design to first-pass execution. This approach replaces reactive troubleshooting with proactive, evidence-based design refinement. Construction teams no longer rely on guesswork; they learn continuously from operational reality.

Measurable Impact

Organizations that adopt this approach see tangible operational improvements:

30% reduction in post-launch defects

Fewer repeat field issues across projects

Reduced rework cycles and higher first-pass success

Increased confidence in design reuse and long-term reliability

The improvement comes not from additional inspections or oversight, but from designs that learn from reality.

Engineer Insight

“By connecting real-world asset performance back into our design models, we stopped repeating the same mistakes. Each completed project now informs the next, improving reliability across all our programs.”

From Static Designs to Learning Assets

Neodustria orchestrates industrial transformation by ensuring engineering remains connected.

Wrong assumptions are replaced with continuously refined models

Recurring defects are caught and prevented before they occur

Lessons from each project accumulate into organizational intelligence

Neodustria enables construction organizations to turn every completed asset into an opportunity for learning, reducing defects, improving efficiency, and increasing confidence in repeat builds.

From Legacy Constraints to Precision Engineering